The Future of Smart Factories and Automation: Trends and Innovations

The Rise of Smart Factories and Automation

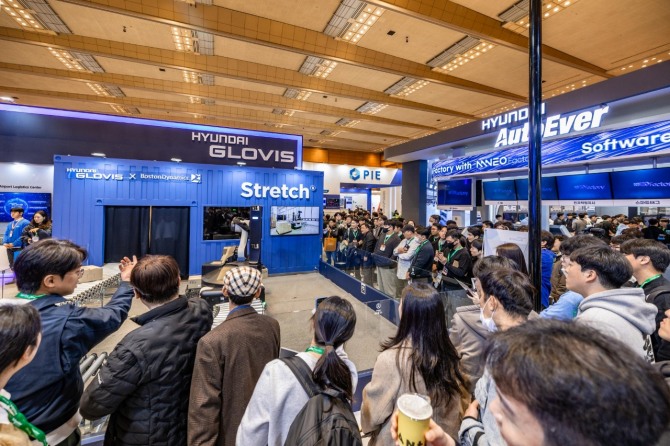

The Asia Smart Factory and Automation Industry Exhibition 2025 (AW 2025) was a monumental event, bringing together 500 companies from 22 countries, 2,200 booths, and over 70,000 visitors. This exhibition highlighted the rapid advancements in smart factory and automation technologies, setting a new benchmark for future industrial events.

Cutting-Edge Technologies on Display

The exhibition showcased a plethora of cutting-edge technologies, including AI, smart factory solutions, big data, cloud computing, logistics robots, and industrial robots. These technologies are transforming traditional manufacturing processes into highly efficient and autonomous systems.

Did you know? The integration of AI and robotics in manufacturing can increase productivity by up to 30% and reduce operational costs by 20%.

Highlights from the Exhibition

Hyundai Glovis Group’s Stretch Robot

One of the standout innovations was the ‘Stretch’ logistics robot by Hyundai Glovis Group and Boston Dynamics. This robot, demonstrated for the first time in Asia, can handle DE-Palletizing tasks, moving up to 23kg of boxes with precision and efficiency. This robot exemplifies the shift towards more agile and versatile automation solutions.

Hyundai Auto Ever’s Neo Factory

Hyundai Auto Ever unveiled its AI-based software-defined factory (SDF) solution, ‘Neo Factory.’ This solution integrates various advanced production equipment, including cooperative robots, autonomous vehicles, and AI vision systems, to enhance manufacturing processes. The Neo Factory represents a significant leap in smart manufacturing, emphasizing the importance of AI and automation in modern factories.

Schneider Electric’s Sustainable Solutions

Schneider Electric, recognized as the world’s No. 1 sustainable company, celebrated its 50th anniversary in Korea. The company introduced its next-generation smart manufacturing solution under the slogan ’50 Years of Innovation: IMPACT for Sustainable Smart Factory.’ This initiative underscores the growing emphasis on sustainability and innovation in the manufacturing sector.

Rockwell Automation’s OTTO 100

Rockwell Automation showcased the OTTO 100, a small autonomous driving robot designed to support factory automation and production logistics. This robot is a testament to the increasing role of autonomous systems in enhancing operational efficiency and reducing human intervention.

Business and Innovation Events

The exhibition also featured various events aimed at maximizing business performance. The Overseas Buyer’s Invitational Export Consultation, organized by the Korea Trade Association, saw participation from 23 buyers from nine countries. This event facilitated 317 exports with 134 domestic companies, resulting in a total of $160 million in deals. Global companies like Telkomcel and Panasonic Indonesia were among the participants, highlighting the international interest in smart factory technologies.

The AW Open Innovation Round, held for the first time, selected six innovative companies to foster startups in the smart factory sector. The selected companies—Mobig Lab, MyLink, Alt.M, Edgros, One Predict, and Power Autorobotics—represent the future of innovation in smart manufacturing.

Future Trends in Smart Factories and Automation

AI and Machine Learning Integration

AI and machine learning are becoming integral to smart factories. These technologies enable predictive maintenance, quality control, and process optimization, leading to significant improvements in efficiency and cost savings.

The Role of Big Data and Cloud Computing

Big data and cloud computing are transforming data management and analysis in manufacturing. These technologies allow for real-time data processing and analytics, enabling smarter decision-making and better resource allocation.

Pro Tip: Implementing big data and cloud computing can help manufacturers predict equipment failures, optimize supply chains, and enhance overall operational efficiency.

Advancements in Robotics and Automation

The development of advanced robots and automation systems is revolutionizing manufacturing processes. These technologies can handle complex tasks with precision and speed, reducing the need for human intervention and enhancing productivity.

Sustainability and Green Manufacturing

Sustainability is becoming a key focus in the manufacturing sector. Companies are increasingly adopting green manufacturing practices and sustainable technologies to reduce their environmental impact and meet regulatory requirements.

FAQ Section

What are the benefits of integrating AI in manufacturing?

Integrating AI in manufacturing can lead to increased productivity, reduced operational costs, improved quality control, and enhanced decision-making through predictive analytics.

How does big data help in smart manufacturing?

Big data enables real-time data processing and analytics, allowing manufacturers to optimize processes, predict equipment failures, and make informed decisions based on comprehensive data insights.

What role do logistics robots play in smart factories?

Logistics robots, such as the ‘Stretch’ robot by Hyundai Glovis Group, automate material handling tasks, improving efficiency, reducing human error, and enhancing overall operational productivity.

The Road Ahead

The future of smart factories and automation is bright, with continuous advancements in AI, robotics, and sustainable technologies. These innovations are poised to transform the manufacturing landscape, making it more efficient, sustainable, and competitive.

Table: Key Innovations and Their Benefits

| Innovation | Benefits |

|---|---|

| AI and Machine Learning | Predictive maintenance, quality control, process optimization |

| Big Data and Cloud Computing | Real-time data processing, predictive analytics, smarter decision-making |

| Advanced Robotics | Enhanced precision, speed, and productivity, reduced human intervention |

| Sustainable Technologies | Reduced environmental impact, compliance with regulatory requirements |

Call to Action

Stay ahead of the curve by exploring more articles on the latest trends and innovations in smart factories and automation. Subscribe to our newsletter for regular updates and expert insights. Share your thoughts and experiences in the comments below, and let’s continue the conversation on the future of manufacturing.